After 376 days of construction, the No. 4 tunnel of Anhui Baomag’s mineral transport corridor project has been successfully completed on July 26, marking significant progress in the construction of the world’s largest magnesium alloy production base. This milestone brings Anhui Baomag closer to becoming the world’s largest, most advanced, and most comprehensive magnesium alloy production base.

The Anhui Baomag mineral transport corridor is a key component of the Baomag Light Alloy core project, which is part of the world’s largest magnesium alloy production base. It is also a “green channel” for the transformation and upgrading of the mining economy in Qingyang County, Chizhou City, Anhui Province. The corridor stretches approximately 22.97 kilometers, comprising enclosed overhead corridors and four mountain tunnels, with an annual dolomite transport capacity of 40 million tons, making it an important logistics route for the mining industry.

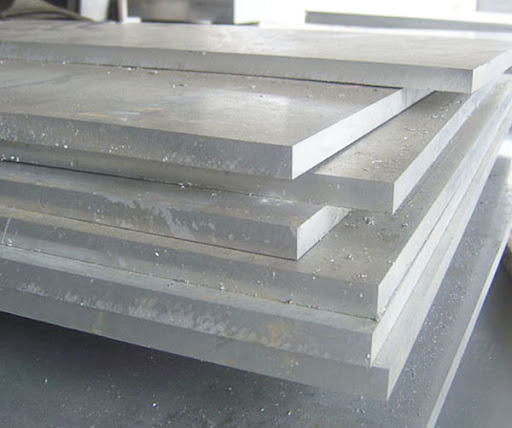

The recently completed No. 4 tunnel is the longest tunnel in the entire corridor project, spanning approximately 1,585 meters. It is the final stage of transporting dolomite from the mining site to the processing plant. Since the tunnel excavation began in July 2023, the China Railway 25th Bureau team has utilized advanced technologies such as TSP and seismic waves to optimize lining methods and adjust support forms, resulting in significant technological innovations that have reduced concrete overruns and construction time, overcoming the severe challenges posed by complex geological conditions to ensure construction safety and quality.

In addition to facing continuous high temperatures recently, the team has implemented staggered construction schedules, avoiding outdoor work during midday heat, and established worker service stations on-site equipped with air conditioning, refrigerators, and other cooling supplies to ensure the safety of workers during summer operations, enabling orderly and efficient construction.

To minimize the impact on the surrounding environment and the safety of residents, the China Railway 25th Bureau team has synchronized environmental protection efforts with the construction process, employing segmented and short-delay blasting methods to reduce blasting volume and vibration amplitude. They have also reduced dust concentrations by 85% through the use of mist cannons and wet spraying methods, ensuring environmentally friendly construction.

According to a representative from Baomag Light Alloy Co., Ltd., the completion of the No. 4 tunnel signifies significant progress in the supporting projects of the world’s largest magnesium alloy production base, indicating that Anhui Baomag is steadily advancing towards a leading position in the global magnesium alloy industry. In the future, this project will become the world’s largest magnesium alloy production base and promote the agglomeration of the magnesium alloy deep processing and lightweight application industries, becoming a new highlight in the regional economy.

[Source – 上海有色网] 全球最大镁合金生产基地配套工程宝镁廊道项目最长隧道贯通 https://news.smm.cn/news/102875139