Recently, the Baotou Rare Earth Research Institute collaborated with Lanzhou University to develop a flexible rare earth fiber aerogel that combines low thermal conductivity with high-temperature resistance, featuring advanced core technical indicators. It is understood that aerogel materials are widely used in chemical insulation, new energy vehicles, and clothing due to increasing demand and performance requirements.

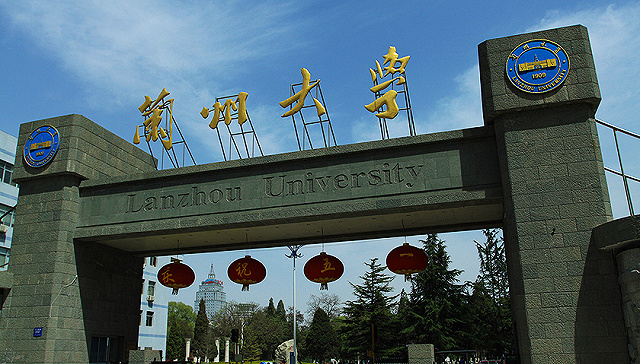

In 2022, the Baotou Rare Earth Research Institute and Lanzhou University cooperated to tackle issues related to the market demand for high-performance thermal insulation materials, and the insufficient toughness and lower working temperatures of traditional ceramic fibers. The collaboration focused on developing high-performance insulation materials characterized by light weight, low thermal conductivity, high-temperature stability, and superior mechanical properties. Through close communication and concerted efforts, they successfully developed a rare earth fiber aerogel material using low-cost, abundant rare earth elements such as lanthanum and cerium. This material has a thermal conductivity as low as 0.012 W/(m·K) at room temperature and ranges from 0.012 to 0.04 W/(m·K) from room temperature to 800°C. It is expected to be widely used in aerospace, chemical and building material insulation, explosion protection for new energy batteries, cryogenic insulation, catalysis, and environmental pollutant management.

The Baotou Rare Earth Research Institute, based on the joint platform with Lanzhou University, shares research and achievements with the university. Together, they have filed for two invention patents surrounding this material. Next, the team will continue to meet market demands, evaluate the material’s combustion resistance, corrosion resistance, and waterproofing properties, refine application system parameters, and address the development and operation of pilot-scale equipment, contributing to the high-quality development of the rare earth new materials sector.

[Source – 上海有色网] 稀土纤维气凝胶材料研发取得新突破 https://news.smm.cn/news/102745742